The Importance of Reliable Fusion Splicing in Modern Networks

In today’s connected world, nearly every critical system whether it’s renewable energy, healthcare, finance, or transportation relies on the invisible backbone of fiber optic networks. At the heart of these networks lies a precision process called fusion splicing, the method of permanently joining two fiber optic strands together. While it may seem like a small technical detail, the reliability of fusion splicing can determine the strength, stability, and longevity of entire communication systems.

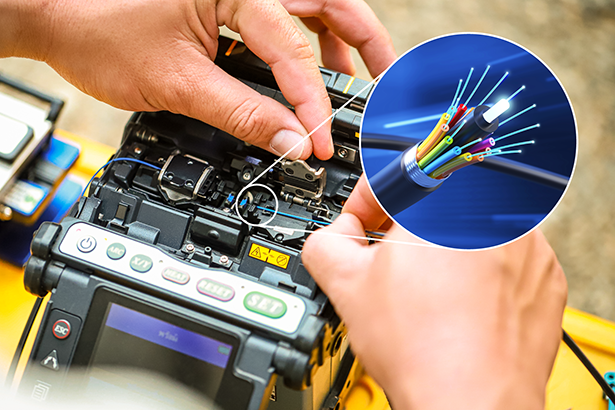

What Is Fusion Splicing?

Fusion splicing is the process of aligning and then “welding” two optical fibers together using an electric arc. The goal is to create a seamless joint with minimal signal loss and reflection. Unlike mechanical splicing, which uses connectors or clamps, fusion splicing delivers a permanent connection with far greater performance and durability. This makes it the industry standard for utility scale projects, data centers, and telecommunications infrastructure.

Why Reliability Matters

The strength of any fiber optic system is only as good as its weakest splice. A poor splice can lead to signal loss, increased attenuation, or even total communication failure. In critical environments like grid tied solar farms, hospitals, or financial trading hubs such failures can result in costly downtime, safety risks, or lost revenue. Reliable fusion splicing ensures that networks perform at their designed capacity, with clear, uninterrupted data transmission over long distances.

Cost and Time Savings

Investing in high-quality fusion splicing upfront can significantly reduce long-term costs. Poor splicing often requires repeated troubleshooting, re-splicing, or even full cable replacement. These corrective measures not only consume time but also drive up labor and equipment costs. By ensuring each splice is executed correctly the first time, project teams save money and prevent delays in commissioning schedules. In large scale construction such as solar and wind farms where thousands of fibers may be spliced this reliability translates into measurable cost efficiencies and smoother project handovers.

Meeting Industry Standards

Fiber optic systems must meet strict performance standards, often dictated by BICSI, FOA, or utility specific requirements. Reliable fusion splicing is essential for ensuring that attenuation levels remain within acceptable ranges, and that documentation from OTDR (Optical Time Domain Reflectometer) and OLTS (Optical Loss Test Set) testing confirms compliance. Without this level of precision, projects risk failing inspections, which can delay energization or regulatory approvals.

Building Resilient Infrastructure

As our dependence on digital infrastructure grows, so too does the demand for resilient communication networks. Whether it’s enabling SCADA systems in renewable energy plants, supporting emergency response networks, or powering global internet traffic, the reliability of fusion splicing underpins the reliability of the entire system. Every precise splice represents a link in the chain of resilience that keeps critical operations online.

Reliable fusion splicing is more than just a technical step in network construction—it’s the foundation of modern connectivity. By investing in skilled technicians, quality equipment, and thorough testing, companies ensure that their networks are built to last. In a world that demands 24/7 uptime and flawless communication, fusion splicing isn’t just important it’s indispensable.